隨著光纖雷射切割機不斷深入市場,越來越多高品質的光纖雷射切割機被開發出來。它們具有高速的切削速度和優異的工件加工質量,優化了切削速度和切削能力。

海目星雷射在中國提供高品質的光纖雷射切割機。本文將以HF-B/C/G/H系列鈑金切割機為例,詳細探討光纖雷射切割機的細節,說明什麼是高品質的雷射切割機,從而將您的製造業務推向新的高度。

纖維切割機零件

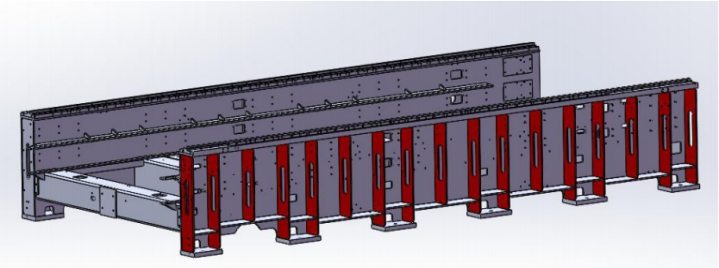

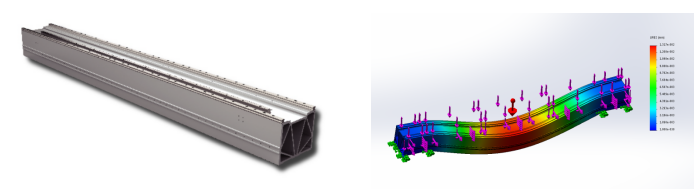

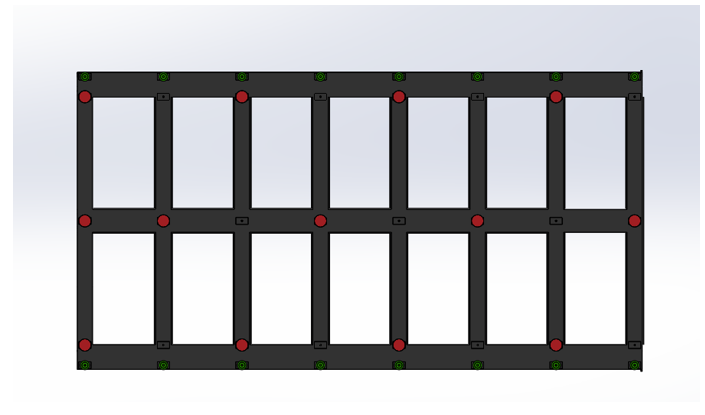

1、蜂窩榫卯結構機床

● 專利設計剛性符合工業工具機標準,具有高強度、高精度、高公差。材料本身和焊接產生的內應力可以透過高溫處理消除。

● 床身採用榫接焊接多龍骨結構,確保工具機高速移動時的穩定性與精度。

●數控光纖雷射切割機切割梁採用鋁合金材質,具有重量輕、剛性強、慣性小等優點。

● 遵循大型工具機設計標準,該工具機通過數據模擬分析和耐用性測試;

● 確保工具機結構穩定和設備長期穩定運作。

HF 6025G數控雷射鋼板切割床身

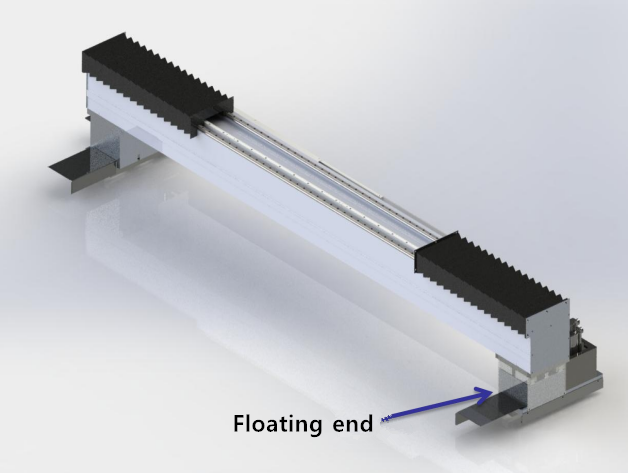

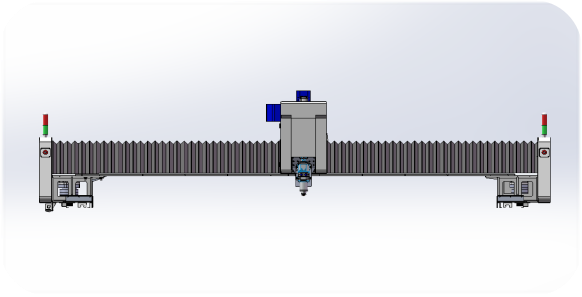

2. 浮動端

橫樑採用蜂巢結構橫樑設計,具有高強度、高剛性、重量輕的優點,保證了橫樑優越的動力性。

● 整體橫樑加高,避免受熱影響。

●雷射切割設備的鋁樑可以在保證受力和動態性能的同時減輕整個機芯的重量

● 床會長期受到外力的影響。因此,樑的一端被設計為浮動結構。主要目的是抵銷床身長期使用時兩側基準平行度影響的影響。經測試,切割精度有明顯保證。

3.雷射切割設備的補償光束

獨特的橫樑結構設計,透過結構優化降低加工難度。橫樑也減少了運動部件的熱脹冷縮力,提高了整機導軌和減速機的使用壽命。

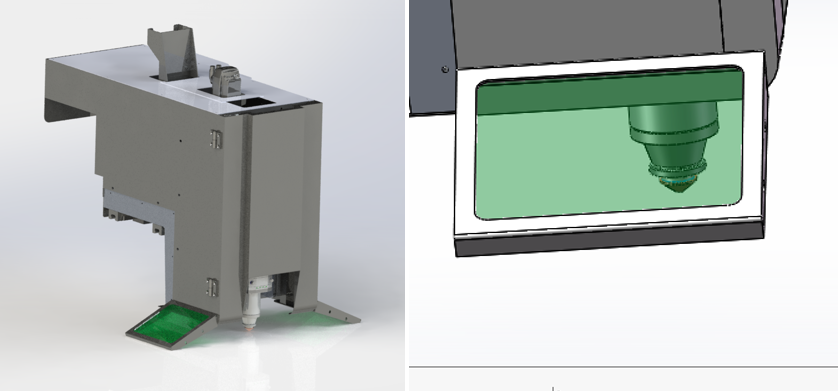

4.光纖雷射切割機Z軸及保護

● Z軸採用鑄鋁滑座,整體加工成型,確保切削運動的穩定性。

● 在切割過程中會產生大量的鐵水飛濺和光源輻射。在圖 1 中,光束周圍放置了紅色防火布,以屏蔽雷射光源和火花。

● Z軸兩側加裝防輻射玻璃;根據測試人員介紹:當工具機兩側距離0.5m至1m時,切割時可有效遮擋光源的輻射,可透過有機玻璃觀察切割狀況。

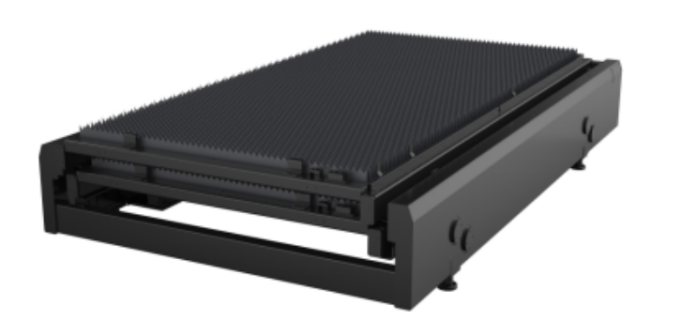

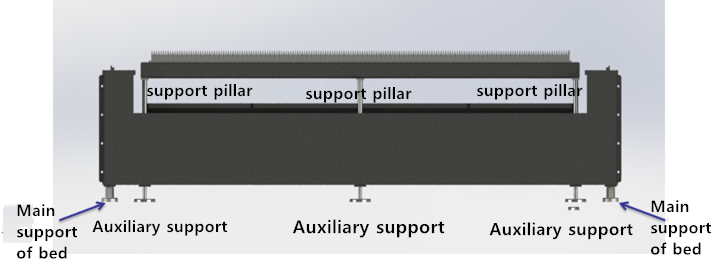

5.床身支撐

● 床體安裝固定有主支撐和輔助支撐

● 功能:數控板材切割機床體加寬,以避免床體在長期使用中在外力作用下,導致平行度受到影響。

● 由於切割區域負載較大,且裝卸頻繁,因此在中間過程中無法避免幾個常見的影響因素(包括重力、振動和切割產生的熱量)。

所以中間三個輔助支撐的目的是支撐切割寬度,將力量透過(支撐柱)直接作用到地面而不是直接施加到清潔床體上,從而確保床體的穩定性。

6.智慧型隨動通氣系統

● 採用分區、分段抽風,透過各分區氣壓缸動作的後續控制,減少不必要的能耗。

● 僅打開切割作業段的通風口,以獲得更集中、更強的風,除塵效果更好

7.精密齒輪傳動

● 配合精度高,咬合率高,轉動更平穩、安靜

● 緊湊的負載驅動結構,有效降低驅動扭矩,抑制振動

● 雙驅動龍門運動系統,可實現更高的加速度和更快的移動速度效果

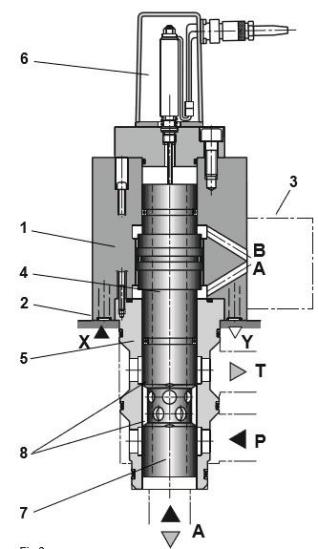

8. 雷射切割頭

● 自動對焦系統

● 輕量化設計,加速快

● 無漂移距離感測器

● 持續監控防護鏡片

● 封閉光路保護

● 自動沖孔

● 冷卻技術,快速冷卻鈑金表面溫度

●LED工作指示燈顯示切割頭狀態

● 可透過無線網路在行動終端或數控系統上讀取監控數據

● 切割頭和噴嘴內設有壓力感測器

雷射切割機切割技術

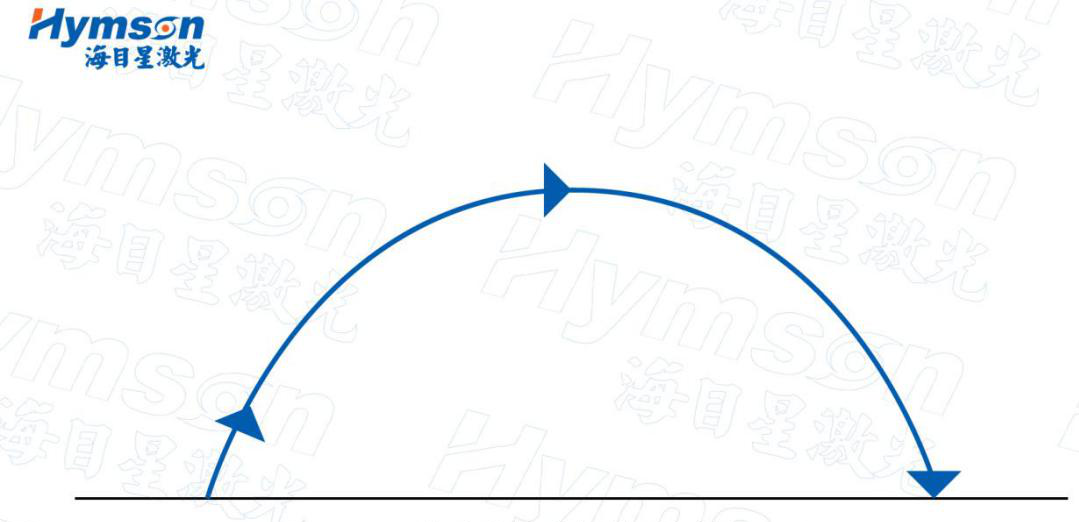

1. 蛙式切割

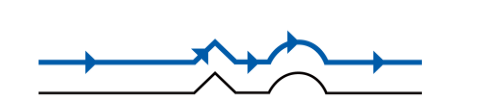

2、自動避障

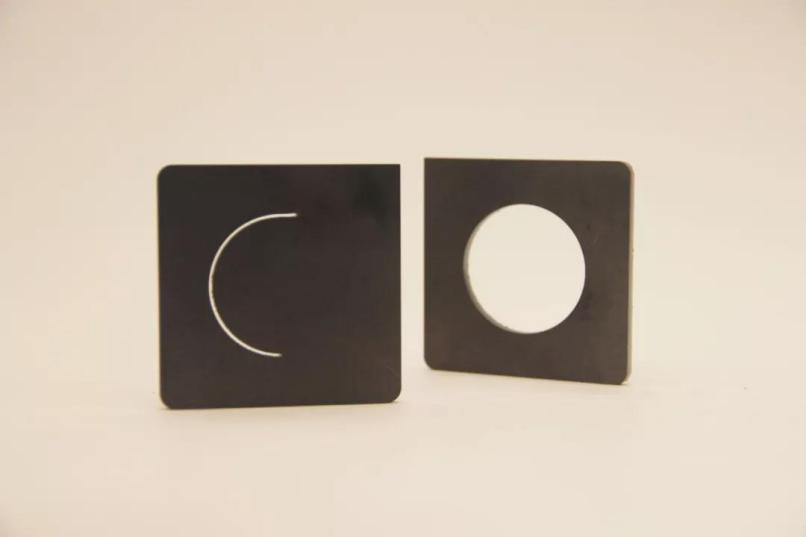

3.鋁合金無毛邊切割(可選)

4.快速穿孔

●效率高:比一般穿孔1-2秒的時間節省80%以上

5.任意點切入

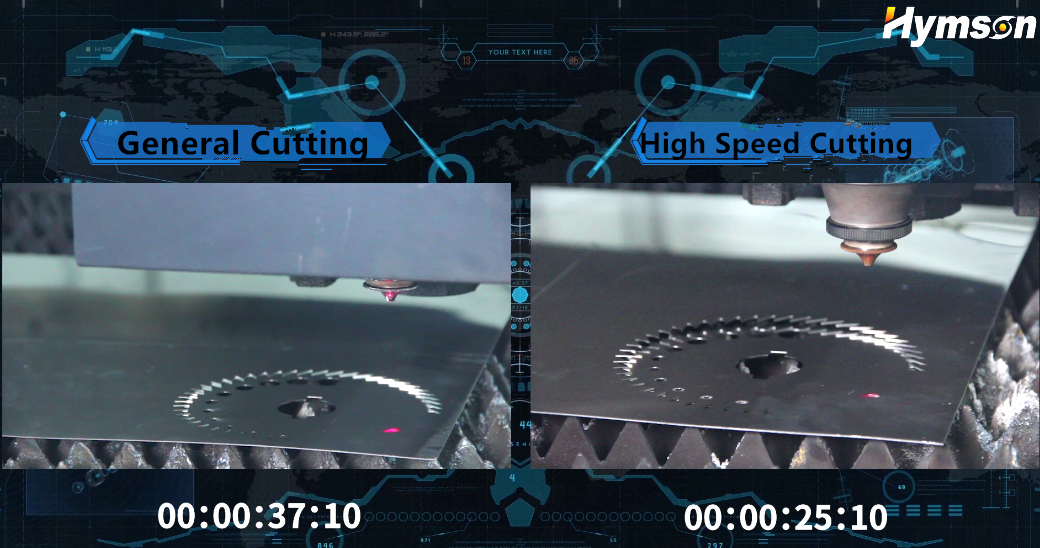

6. 高速切削

●一般快速加減速,如劇烈衝擊震動、齒條斷裂等,可能會損壞車床的硬體。

雷射切割機的管材糾偏功能

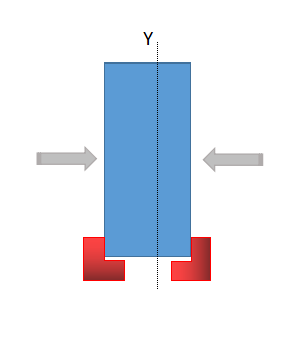

● 彎管中心糾偏功能,使三種常規管材(方管、矩形管、腰管)在切割過程中達到中心偏移功能。

鋼材雷射切割機的這項功能還可確保輪廓位於管材表面的中心位置,減少因管材彎曲而造成的輪廓兩側不對稱。

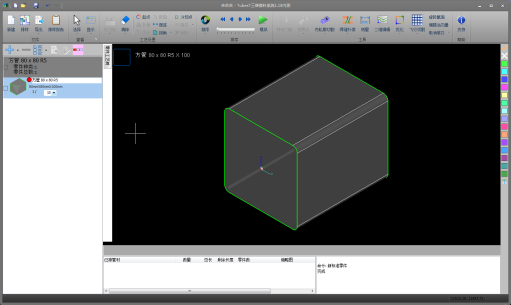

雷射切割設備軟體

● TUBEST是一款集設計、生產於一體的鈑金CAD/CAM自動化程式設計軟體。支援全流程數控操作,包括繪圖、自動或互動式加工、數控程式模擬、手動和自動切割、加工程式下載和上傳。

● 可以直接輸入Solidwork軟體產生的圖形檔。

● 簡單易用。

雷射切割機如何運作?

分享這篇文章: