CNC鋼板切割機製造商、供應商、工廠

海目星一直致力於以具有競爭力的價格提供高品質、卓越的產品和解決方案。作為中國領先的鋼板切割機製造商之一,我們有能力同時快速交付光纖雷射切割機、板材雷射切割機、管材雷射切割機、精密雷射切割機和雷射切割機焊接機。我們將不斷努力改進我們的供應商,並以優惠的價格提供最優質的產品和解決方案。如有任何詢問或評論,我們將不勝感激。請自由地聯絡我們。

海目星雷射是專業的智慧鋼板切割機製造商之一,是新能源汽車、消費性電子、金屬製造行業自動化系統的領先供應商。產品將供應歐洲、美洲、澳洲、瓜地馬拉、緬甸、斯洛維尼亞、阿聯酋等世界各地。我們擁有一支合格的國際貿易銷售團隊,具有多年的良好服務和發展。我們的產品已出口至北美、歐洲、日本、韓國、澳洲、紐西蘭、俄羅斯等國。期待未來與您建立良好、長期的合作!

汽車產業的優勢

- 平滑切割。光纖雷射切割機由電腦控制,可以精確地切割材料。

- 生產效率高。雷射切割設備加工面大,可加工整板。

- 光纖雷射切割機的成本低於傳統的加工方法。

- 加工靈活。在切割中小批量、大面積、複雜輪廓的板材時,雷射切割機更加靈活,可滿足個人化需求。

數控鋼板切割機切割不均勻的原因有很多。在切割不同的金屬板材和不同厚度的材料時,不同的切割電源和割炬具有不同的技術參數。在切割工作中,應參考設備和工件選擇合適的切割速度標準。鋼板切割機廠商提供了數控鋼板切割機的參數設置,一起來看看吧!

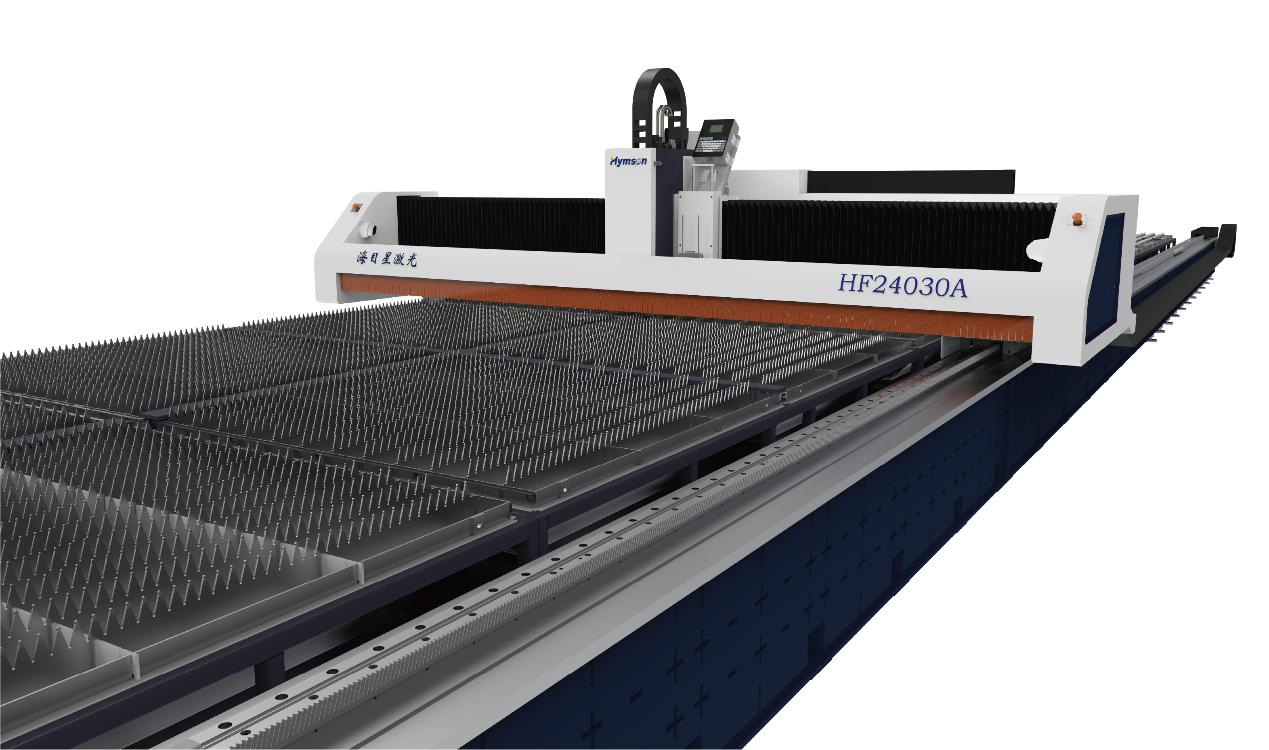

超大尺寸光纖雷射切割機,用於高品質金屬板材雷射切割

超大尺寸光纖雷射切割機的優勢

● 切割效率高、性價比高、運作成本低

● 對銅/黃銅、鋁、不銹鋼和碳鋼具有高切割性能

特徵:

1. 超大尺寸辦公桌

2、優化配置,切割能力強大

光纖雷射金屬切割機的切割電流

它是光纖雷射金屬切割機最重要的切割製程參數,直接決定切割的厚度和速度,即切割能力。影響:

- 切割電流增大,電弧能量增大,切割能力增強,切割速度相應提高;

- 如果切割電流過大,噴嘴的熱負荷就會增大,噴嘴就會過早損壞,切割品質自然就會下降,甚至無法進行正常切割。因此,切割前應根據材料的厚度正確選擇切割電流和相應的噴嘴。

- 切割電流增大,電弧直徑增大,電弧變粗,使切口變寬。

為什麼選擇海目星雷射-鋼板切割機廠商

● 智慧排塵系統:僅作用於切割區域,加強通風效果。

●智慧型瓦斯控制系統:節省瓦斯高達50%

● 自動對焦:準確、快速、智能

● 全自動潤滑系統:自動潤滑齒輪、齒條,免維護。

● 由全球工廠培訓的工程師進行安裝/培訓和支援。

分享這篇文章: