The world of manufacturing is changing fast, thanks to new tech, economic shifts, and our growing focus on being green. Laser cutting, once just a tool for metalwork, is now a big part of the changes. It’s a key part of the latest industrial revolution, helps us move products quickly, and is the foundation of how we make things today.

For businesses that make and work with things, especially in places like Europe, America, the Middle East, and Southeast Asia, keeping up with these changes is crucial. By 2025, laser cutting will be even more important because of a few big trends: the need for super-precise and fast work, smarter automation, the importance of software, the push for sustainability, and the ability to work with more kinds of materials.

This analysis breaks down these trends, giving businesses a plan to stay ahead and find new chances in the future.

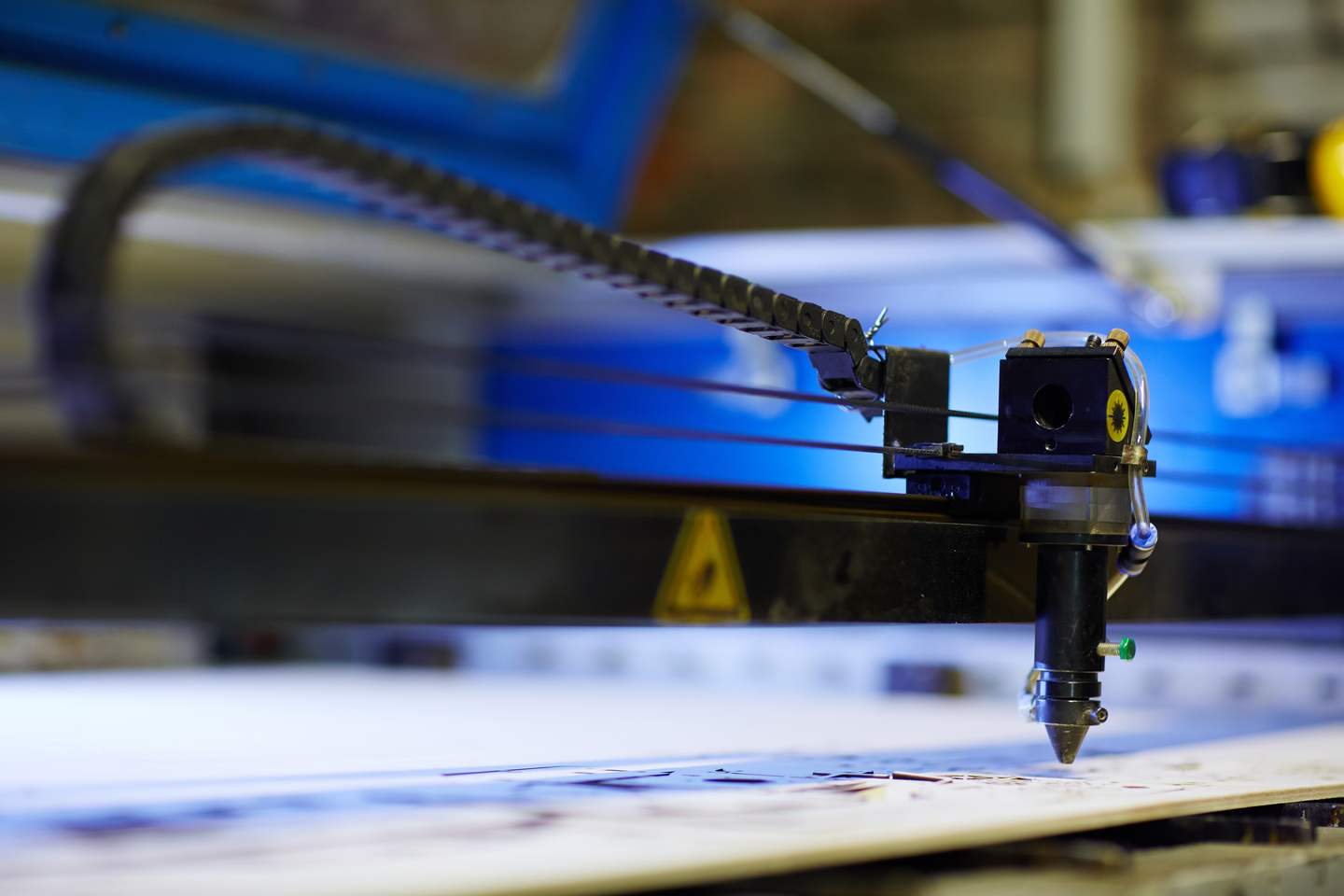

Fiber Lasers: The New Standard in Precision Cutting

The face-off between CO2 and fiber lasers is history, with fiber lasers taking the lead. They’ve set new benchmarks for how we cut materials, making them more efficient, faster, and cost-effective. This trend is set to soar by 2025.

The Science Behind Fiber Lasers’ Success:

Fiber lasers win because they have a shorter wavelength that absorbs better into metals, resulting in much faster cuts—especially on thinner stuff.

For companies, especially those in places like the UAE that care about energy use, fiber lasers save a lot on electricity and don’t need costly gases. They also need less maintenance, which means less downtime and more productivity.

The Rise of Power and Versatility:

Fiber lasers used to be great for thin metals, but now they can handle thick ones too. With more power available, they can cut through thick steel and aluminum, competing with other cutting methods. This means one machine can do a lot of different jobs, from detailed work to heavy fabrication.

Innovation Beyond Power:

New tech in laser cutting isn’t just about having more power. Features like beam shaping and “wobble head” tech are now common, which help make cleaner cuts, reduce waste, and handle materials that were tough for fiber lasers before. This focus on quality means parts are almost ready for the next step in production, cutting down on extra finishing work.

The Future of Factories: Software and AI Take the Lead

In laser cutting, the hardware is the power, and the software is the smarts. Good software can make all the difference in manufacturing success. This trend is all about using smart algorithms and data to get the most out of every piece of metal and every minute of work.

Smart Nesting:

Nesting, or arranging parts on a sheet to waste less material, has gotten really smart. Modern software can:

Share cut lines between parts to save time and materials.

Keep track of leftover material for future small jobs.

Learn from past jobs to get better at nesting complex parts over time.

AI on the Factory Floor:

AI is taking over jobs that used to need experienced workers:

Set cutting parameters automatically based on the material and part details.

Create accurate quotes in seconds by analyzing customer files and calculating costs.

Managing from the Cloud:

Cloud technology is making it easier to manage laser cutting operations:

Check on machines and jobs from anywhere.

Upload new programs remotely.

Get automatic updates to keep the machine running smoothly.

This is a game-changer for businesses with multiple locations or managers who need to stay in touch while away from the factory.

Sustainability and Energy Efficiency

Being green isn’t just about doing good—it’s good for business. With stricter regulations, higher energy costs, and customers demanding eco-friendly products, manufacturers are looking for ways to reduce their environmental impact.

Fiber Lasers: The Sustainable Choice

Fiber lasers are more energy-efficient than older technologies, which means they have a smaller carbon footprint. They also use fewer consumable parts and don’t need laser gases, making them a greener option.

Waste Reduction Beyond Energy

Sustainability is about more than just saving energy. It’s about reducing waste in all forms:

Material Waste: Advanced nesting software can save a few percentage points on material use, which adds up to a lot of metal and energy saved over time.

Gas Consumption: New methods are optimizing nitrogen use, and high-pressure air cutting is a cost-effective alternative for many applications, reducing reliance on bottled nitrogen.

Circular Economy: Efficient part sorting and remnant management keep materials in the production loop longer, increasing their value for recycling.

For companies in the Europe, America, the Middle East, and Southeast Asia, adopting green technologies aligns with national sustainability goals and enhances their reputation.

Customization and Specialized Applications

Laser cutting is moving beyond traditional sheet metal work into niche markets and specialized applications. This trend is driven by the technology’s versatility and the demand for customized, high-value products.

Tube and Profile Cutting

The market for tube and profile cutting is growing fast. Advanced machines can cut tubes and profiles with precision, creating complex joints and features in a single process. This is transforming industries like construction, furniture design, and automotive.

Expanding Material Options and Micro-Machining

Innovations are expanding the range of materials that lasers can cut, including composites, plastics, and advanced alloys. On the other end, micro-machining is creating microscopic features for industries like medical devices, electronics, and aerospace.

Navigating the Future of Fabrication

The future of laser cutting is about intelligence, integration, and responsibility. Agility, data-driven decisions, and sustainable practices will define leading fabrication businesses. Trends like fiber laser dominance, automation, software optimization, sustainability, and customization are interconnected, pulling the industry toward a more efficient and automated future.

Staying informed is the first step, but decisive action is what will separate the leaders. Whether upgrading existing equipment or investing in your first laser cutter, choose a partner who provides training, support, and strategic insights to navigate this dynamic landscape. The future of fabrication is here, powered by the precise beam of a laser.

FAQs:

Q1: Are advanced fiber laser machines and automation systems affordable for a small workshop?

A1: Yes, technological maturity is making powerful fiber laser technology more accessible. Entry-level machines offer efficiency and capability at a competitive price. Automation is modular, so you can start with a standalone machine and add systems as you grow. Calculate ROI based on increased speed, energy savings, reduced labor, and material savings.

Q2: How difficult is the transition from CO2 to fiber laser systems?

A2: The transition is smoother than you might think. Modern controls and software are intuitive and user-friendly. The biggest change is in maintenance, which is simpler for fiber lasers. Reputable suppliers provide comprehensive training to ensure a seamless transition.

Q3: How complex is the new generation of CAD/CAM and nesting software?

A3: Modern software is powerful yet intuitive, with graphical, touch-screen controls and guided workflows. Many complex tasks are automated by the software’s intelligence. Proper training will have operators proficient in the new software faster than expected.

Q4: How can I calculate the Return on Investment (ROI) for a new fiber laser cutter?

A4: Consider increased throughput, energy savings, material savings, labor savings, and consumable & maintenance savings. A good supplier can help you with this calculation.

Q5: Can a single fiber laser machine cut everything from steel and aluminum to tubes and composites?

A5: While fiber lasers are versatile, there isn’t a single machine for every material and format. Discuss your current and future needs with your supplier to configure a machine that offers the best versatility for your business.

分享這篇文章: