Introduction: Choosing More Than Just a Machine

The industrial laser cutting market is entering a new phase of rapid evolution, with fiber laser technology becoming the driving engine of precision manufacturing globally. For laser cutting machine distributors, the golden question in 2025 is not only “which machine has the best specs?” but “which manufacturer can help you scale profitably, reliably, and sustainably? ” Choosing a supplier today is effectively choosing your business capacity for tomorrow.

In this guide, we focus on Hymson, a global manufacturer widely regarded for its robust high-speed fiber laser solutions. With a balanced view of technology and business viability, we break down their two flagship models—the HF-G Series and HF-3216 Series—to help you select the right machine for your portfolio and understand the added value of manufacturer partnership in this competitive landscape.

CONTENTS

- The Foundation of Trust: Why Your Manufacturer’s Profile Matters

- Performance Deep Dive—Comparing Hymson’s High-Speed Solutions

- Strategic Selection for Your Portfolio—Model Comparison & Advice

- Beyond the Specs—Business Support and Profitability Model

- Make the Strategic Move in 2025

- Frequently Asked Questions

The Foundation of Trust: Why Your Manufacturer’s Profile Matters

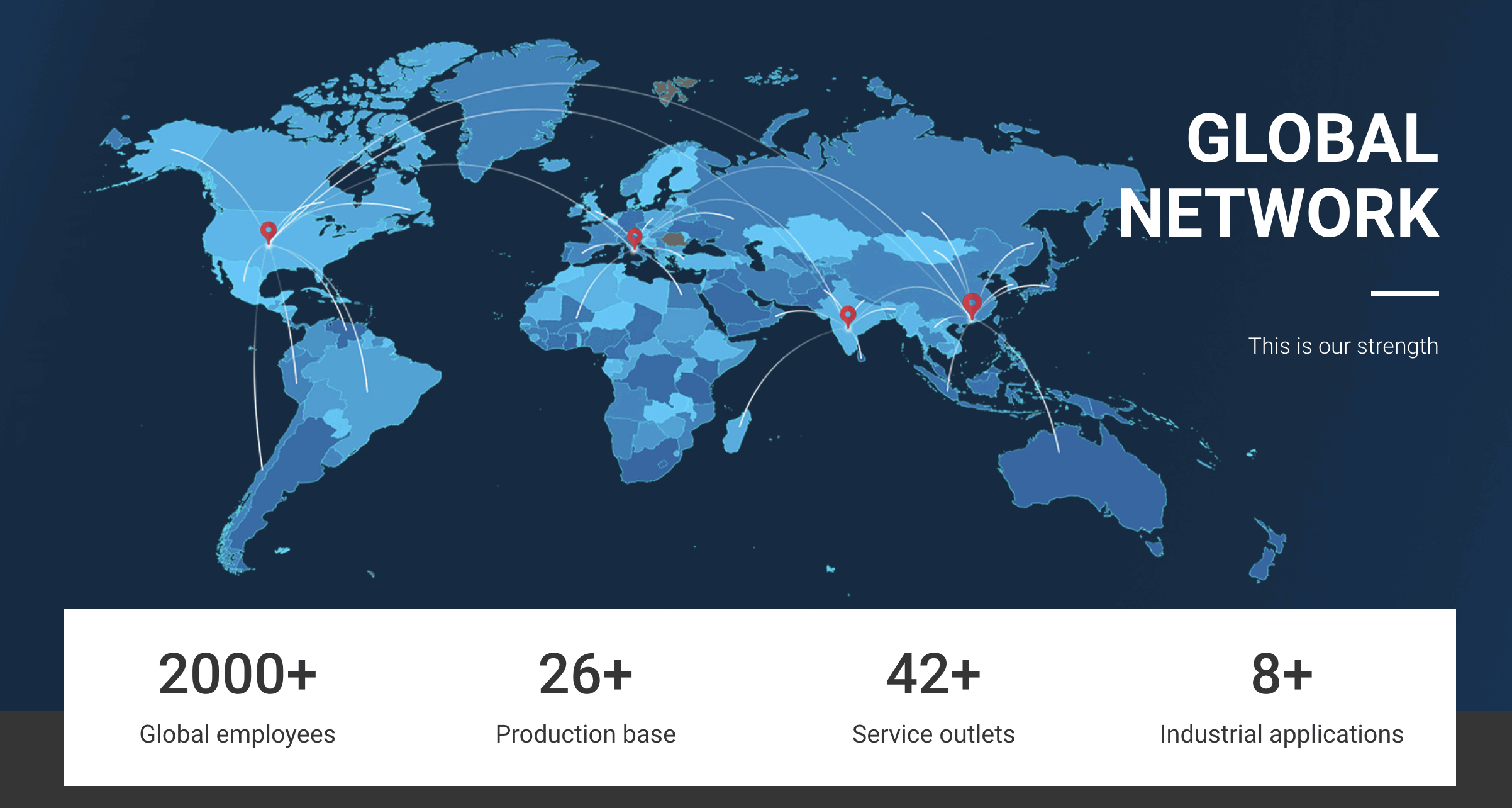

Brand trust and corporate stability are often underestimated assets in long-term distributorship success. Hymson is a strategic example of how a supplier’s vision, infrastructure, and market engagement directly amplify their distributor’s capacity.

Founded in Shenzhen, China, Hymson operates advanced production and R&D hubs across Jiangmen, Anshan, and Jiangsu, while maintaining international subsidiaries and service teams in Italy, Korea, and the United States. This ensures that distributors benefit from localized response, efficient part delivery, and borderless support.

Beyond hardware, Hymson positions itself as a “Laser + Automation” solution provider. Rather than merely selling metal cutting machines, Hymson delivers integrated production-line solutions for sheet metal, pipe cutting, 3D part manufacturing, and welding—ideal for clients seeking smart factory upgrades.

Performance Deep Dive—Comparing Hymson’s High-Speed Solutions

When it comes to product performance, Hymson offers two high-speed fiber laser cutting machine series that suit diverse industrial needs:

HF-G SERIES—For High-Speed Mass Production

The HF-G Series is designed for high-efficiency batch production. It offers:

- Cutting speed increase of 50–100% compared to conventional machines

- Acceleration of up to 1.5 g

- Positional accuracy of ±0.03 mm/m

- FSCUT industrial control system (real-time EtherCAT communication, remote diagnostics)

It features a patented mechanical guide structure, a high-rigidity modular base, a precision gear drive configuration, and a lightweight aluminum beam. This ensures long-term accuracy even in high-speed operations. Its dual-platform design enhances production continuity, making it ideal for high-demand sectors like automotive parts or appliance manufacturing.

HF-G SERIES HIGH SPEED FIBER LASER CUTTING MACHINE

HF-3216 SERIES—For Stability and Long-Term ROI

The HF-3216 Series focuses on structural stability, repeatability, and durability in industrial environments:

- Designed with hollow-section machine bed and high-temperature annealing to reduce stress

- Dual-motor gantry design with aluminum extrusion beam and high-efficiency ventilation

- Modular build enhances heat dissipation and operation in multi-shift environments

Though specific acceleration or precision specs are not publicly available, this design suggests a machine qualified for precision component manufacturing, aerospace parts, and heavy-duty multi-layer material processing.

HF·3216 HIGH SPEED SERIES FIBER LASER CUTTING MACHINE

Strategic Selection for Your Portfolio—Model Comparison & Advice

When advising clients, matching applications to machine strengths is key. Below is a summarized comparison:

|

Spec/Series |

HF-G Series |

HF-3216 Series |

| Application Use |

High-throughput, fast-cycle production |

Stability-focused, precision fabrication |

| Structural Focus |

Rigid welded base, aluminum beam |

Hollow bed, annealed frame |

| Controller | FSCUT (real-time EtherCAT) | ---(Not disclosed) |

| Acceleration/Speed |

Up to 1.5g, cutting speed 50–100% |

High-load stable operations |

| Ideal Industries |

Appliances, automotive sheet metal, HVAC |

Aerospace, engineering steel structures |

Recommendation for Distributors:

- Choose HF-G if your target clients require fast cycle times, high-volume delivery, and a competitive edge in output.

- Choose HF-3216 for clients focused on long-term processing stability, minimal deformation, and component quality assurance.

Beyond the Specs—Business Support and Profitability Model

For distributors, long-term success ties closely to pricing transparency, after-sales support, and value-generating services.

Distributor Margins & Tangible ROI

Hymson offers structured pricing models that enable competitive reseller margins. Moreover, machines support recurring revenue via:

- Consumables (lenses, protective windows, nozzles)

- Periodic maintenance or performance upgrades

- Optional automation packages or software updates

- After-Sales & Technical Support

With service offices and local engineers in regions like North America and Europe, Hymson guarantees fast on-site response, replacement availability, and remote diagnostics. This improves customer satisfaction and reduces your technical support liability.

Ease of Training & Operation

Machines such as HF-G come equipped with FSCUT systems that reduce onboarding time. Hymson provides technical manuals, online support, and on-site training tailored for both operators and distributor engineers.

Compliance & Certifications

All Hymson machines meet CE and ISO standards, supporting safe installation and reducing legal or regulatory friction for regional sales.

Make the Strategic Move in 2025

Distributors must move beyond just shipping machinery in 2025. True success lies in strategic selection—picking equipment backed by a manufacturer that offers global capability, verified engineering, and deep after-sales support.

Hymson stands out not merely as a supplier but as a long-term business partner, helping distributors scale through complete support, ROI-focused models, and evolving product lines fit for advanced manufacturing.

Looking for advice tailored to your target industry? Read our detailed industry-machine matching guide → How to Choose the Right High-Speed Fiber Laser Cutting Machine for Your Industry

Your growth in 2025 starts with the supplier you trust today.

Frequently Asked Questions

Q1: What industries best fit the HF-G and HF-3216 models?

A: HF-G is ideal for automotive, appliance, and HVAC sheet metal. HF-3216 suits aerospace, engineering steel, and precision component fabrication.

Q2: Can distributors access training materials and live support?

A: Yes, Hymson provides comprehensive documentation, remote setup assistance, and on-site training for both clients and partners.

Q3: Is there a local spare parts warehouse in the US or EU?

A: Yes, Hymson maintains regional spare parts warehouses in America and Europe with localized service support.

Q4: What is FSCUT and why is it important?

A: FSCUT is an advanced laser control system offering real-time cutting feedback, diagnostics, and smart automation—reducing operation errors and training time.

分享這篇文章: