Introduction: Industry-Specific Demands Require Tailored Machine Solutions

Mass production industries such as automotive, household appliances, and HVAC manufacturing rely on speed. But they also require consistency, flexible cutting capability, and precise repeatability. As a distributor or application engineer, matching clients with the right machine means identifying these subtle—but critical—production factors.

In this article, we dive into why Hymson’s HF-G Series high-speed fiber laser cutting machine is purpose-built for these sheet metal sectors. We’ll explore common challenges in each industry and how HF-G’s performance, system design, and platform advantages directly address these production pain points.

CONTENTS:

- Typical Sheet Metal Processing Needs by Industry

- Pain Points in Automotive, Appliance & HVAC Fabrication

- How HF-G Series Solves Real Production Bottlenecks

- Machine Performance Reference by Application Requirements

- Internal Guidance: Bundle with Automation for Maximum Value

Typical Sheet Metal Processing Needs by Industry

Let’s begin with what each industry requires from their cutting systems:

|

Industry |

Common Materials |

Cutting Requirements |

|

Automotive |

Mild steel, galvanized steel |

High-speed contour cutting, batch repeatability |

|

Household Appliances |

Cold-rolled stainless steel |

Fine holes, clean edges, uniform rounding |

|

HVAC |

Thin galvanized sheet, aluminum |

High-speed punching, low burrs, consistent depth |

These industries typically run in high volumes using thin to medium sheet metal. The cutting process often involves complex geometries, multi-component panels, and consistent edge quality at fast cycle times.

Pain Points in Automotive, Appliance & HVAC Fabrication

While their production scales are impressive, the following are common issues these industries face:

- Throughput Limitations: Conventional laser machines may bottleneck under high-speed production.

- Distortion Risk: Inconsistent thermal control during cutting can cause material warping in thin sheets.

- Labor Dependency: Frequent manual loading/unloading increases downtime and error potential.

- Complex Geometry Accuracy: Maintaining precision on curves, micro-holes, and tight corners is challenging.

For HVAC and appliance production in particular, edge quality must meet aesthetic and functional standards—while automotive producers demand accuracy in repeat volumes at high speed.

How HF-G Series Solves Real Production Bottlenecks

Hymson’s HF-G Series is engineered to directly solve these problems with:

- 1.5g Acceleration: Ensures top-tier speed and motion control for curved and linear cuts.

- ±0.03 mm/m Precision: Maintains tight tolerance even under dynamic paths.

- Aerospace-grade Aluminum Beam: Lightweight for acceleration, doesn’t compromise stability.

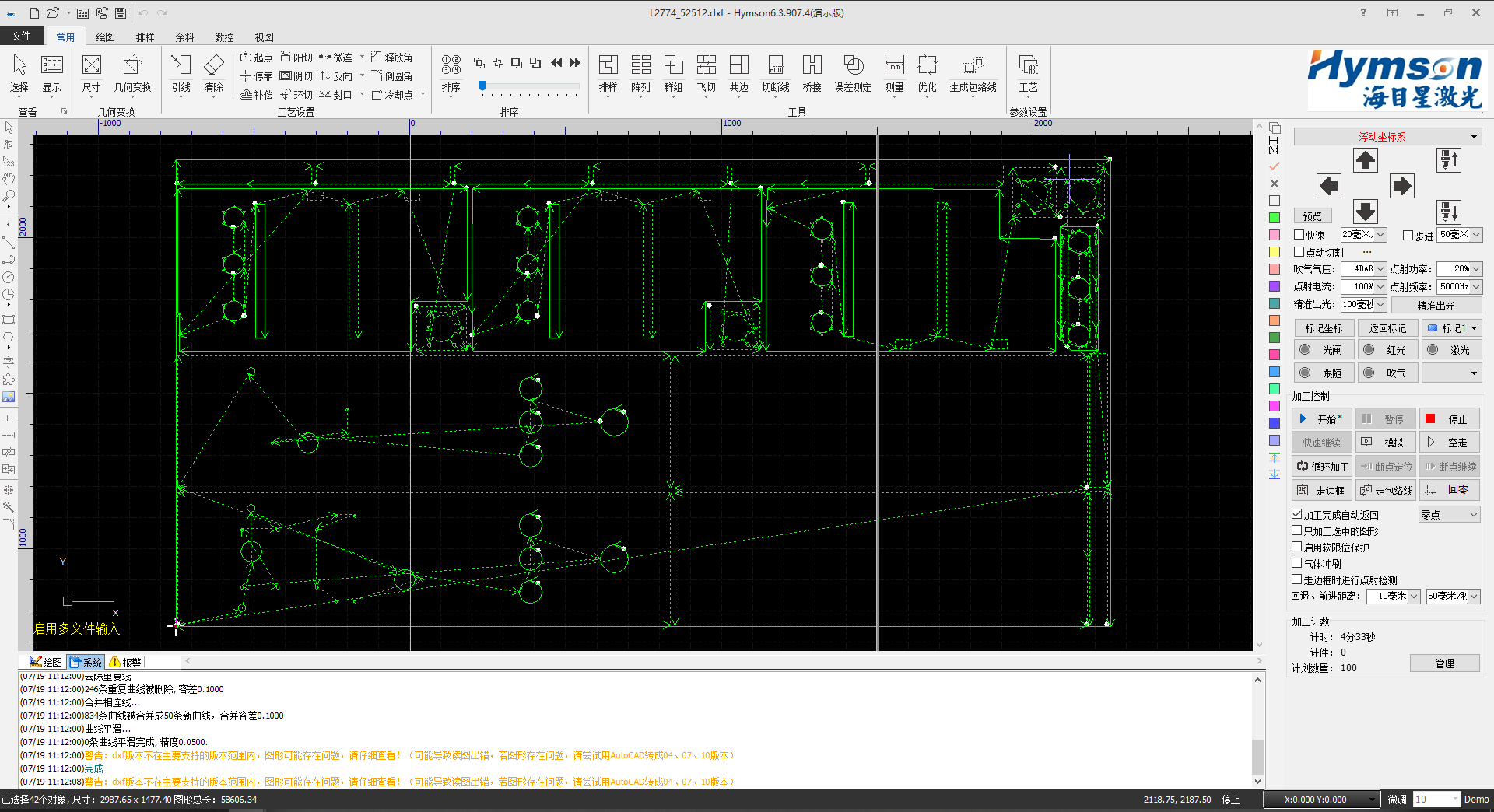

- FSCUT Control System: Real-time EtherCAT data transmission, automated calibration, and diagnostics.

- Dual Pallet Exchange Platform: Seamless sheet transition reduces idle time significantly.

- Modular Chassis Design: Offers heat resistance, full section ventilation, and structural rigidity.

Combined, these features enhance cycle time, accuracy, and system stability—exactly what high-volume sheet metal manufacturers need.

Machine Performance Reference by Application Requirements

Depending on fiber laser power source (1.5 kW–20 kW)

Case Insight Example:

|

Model |

Cutting Range |

Material Thickness |

Accuracy |

Acceleration |

Ideal Industries |

|

HF3015G |

3100×1550 mm |

Up to 25–30mm |

±0.03 mm/m |

1.5 g |

Automotive parts, HVAC ducts, appliance metal |

|

HF4020G |

4000×2000 mm |

Up to 30mm |

±0.03 mm/m |

1.5 g |

Auto body, elevators, large panels |

These specifications are commonly adopted in medium-to-high volume production scenarios where speed and dimensional precision must coexist.

Operators working with vented panels, perforated enclosures, or body panels typically benefit from the HF-G’s dual platform exchange system and nested job strategy supported by its FSCUT controller.

Internal Guidance: Bundle with Automation for Maximum Value

For distributors, pairing the HF-G series with Hymson’s optional automation modules—like robotic arm handling, intelligent nesting, and real-time MES linkage—can deliver end-to-end digital workshop solutions. This speaks directly to factories upgrading toward an Industry 4.0 goal.

Need an overview of brand-level advantages and decision points? Refer to our first article: How to Choose a High-Speed Fiber Laser Cutting Machine in 2025.

Need industry-to-machine mapping? Read: How to Choose the Right High-Speed Fiber Laser Cutting Machine for Your Industry.

Frequently Asked Questions

Q1: What makes HF-G better than universal fiber laser machines in these industries?

A1: It’s the integration of high acceleration, sheet transition speed, and a cutting algorithm optimized for repetitive curvature that makes the HF-G superior for high-volume, thin-to-mid sheet applications.

Q2: Can the HF-G series handle both small and large part processing?

A2: Yes. With various laser power options and bed sizes like 3015 and 4020, the HF-G series can accommodate everything from vent components to full panel shells.

Q3: How do customers typically integrate HF-G into their existing line?

A3: Many users start with semi-automatic setups (dual platform), then add auto-loading systems or MES connectors. Hymson provides integration support at each stage.

Q4: What kind of training or learning curve should an operator expect?

A4: Thanks to FSCUT controls and Hymson training packages, most operators become proficient within 2–4 working days.

分享這篇文章: